brinell hardness test reading|brinell hardness test pdf : factory Brinell hardness testing is a commonly used method for determining the hardness of metals and alloys. The Brinell hardness test formula. When measuring hardness using the Brinell method, . Resultado da 2 dias atrás · Quinielas de Hoytodas las cabezas y premios. ¡¡Bienvenido a QuinielasYa.com.ar!! Quinielas, Loterias, Loto Plus, Quini 6, Telekino, .

{plog:ftitle_list}

webA severely broken arm reveals a bizarre case of bone loss and ends the comeback plans of major league pitcher Hank Wiggen. House suspects Hank is lying about using steroids, .

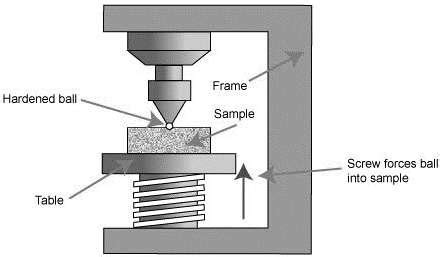

The Brinell hardness test records the diameter and depth of the indentation caused by a ball-shaped indenter, with the indenter pressed into a material’s surface. This is .

🕑 Reading time: 1 minute. The Brinell hardness test is an optical testing method for samples with coarse or inhomogeneous grain structure. This is the best .The Brinell scale /brəˈnɛl/ characterizes the indentation hardness of materials through the scale of penetration of an indenter, loaded on a material test-piece. It is one of several definitions of hardness in materials science.Brinell hardness testing is a commonly used method for determining the hardness of metals and alloys. The Brinell hardness test formula. When measuring hardness using the Brinell method, .

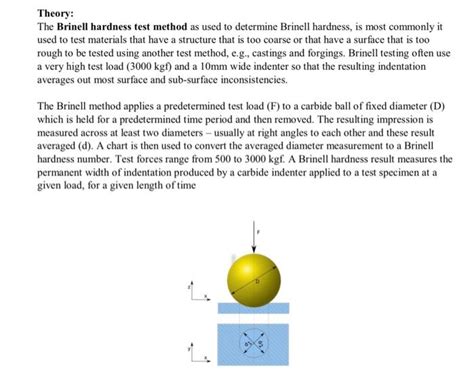

The Brinell hardness test method as used to determine Brinell hardness, is defined in ASTM E10. Most commonly it is used to test materials that have a structure that is too coarse or that have a surface that is too rough to be tested . In this article, we have seen the Brinell hardness test and its two different methods – Standard and Non-Standard Brinell hardness tests. Also, discussed its advantages, disadvantages or limitations, and applications.A well structured Brinell hardness number reveals the test conditions, i.e., "70 HB 10/500/30" which means that a Brinell Hardness of 70 was obtained using a 10mm diameter hardened steel ball with a 500 kilogram load applied for a .Brinell testing of a material with different ball diameters and test forces must be conducted within the same force-diameter index ("Brinell test procedure") in order to enable direct comparison .

Brinell Hardness Test. Basic principle and practical procedure of the Brinell hardness test - Testing machine - Test piece - Spherical indenter - Basic principle - Definition of the. The surface condition has a significant influence on the hardness reading, so improper surface preparation can give inaccurate or spurious readings. Most hardness tests are designed for flat surfaces, so curved .This method requires optical reading of the diameter of ball indentation and using a chart to convert the average measurement to Brinell hardness value. We offer low-cost handheld Brinell scopes as well as a popular line of Automatic .

1.5 At the time the Brinell hardness test was developed, the force levels were specified in units of kilograms-force (kgf). Although this standard specifies the unit of force in the International System of Units (SI) as the Newton (N), because of the historical precedent and continued common usage of kgf units, force values in kgf units are provided for information . Brinell Indentation Diagram. In the standard method of the Brinell Hardness Test, we use 250 to 500 kg of load for soft material and 500 to 3000 kg of load for hard material such as steel and iron. When the Brinell hardness test cannot be used, such as when the material’s HB value is greater than 450 or the sample size is too small, the Rockwell hardness test is used instead. This test involves pressing either a diamond cone with a top angle of 120° or a steel ball with a diameter of 1.59 mm or 3.18 mm into the surface of the tested . Portable and Easy to Use: The portable Brinell hardness tester is small in size, making it easy to carry and operate. It is a convenient tool for determining the Brinell hardness of ferrous metals, metals, and the tensile strength of steel products.

The Brinell hardness test involves pressing a small metal ball into the surface of the test material with a known amount of force. The resulting indentation is then measured and converted into a hardness number. Brinell hardness of some materials. Material. Brinell Hardness. Copper. 35 HB. Aluminum (pure) 15 HB. AW-6060 aluminum.

1.5 At the time the Brinell hardness test was developed, the force levels were specified in units of kilograms-force (kgf). Although this standard specifies the unit of force in the International System of Units (SI) as the Newton (N), because of the historical precedent and continued common usage of kgf units, force values in kgf units are provided for information .In the Brinell hardness test, an optical method, the size of indentation left by the indenter is measured. In contrast to the likewise optical Vickers method,which involves a pyramid-shaped indenter being pressed into a specimen, the Brinell method uses a spherical indenter. The HRB scale typically is used for soft materials such as aluminum and brass alloys. It uses a 1/16-in. ball indenter with a 100-KG test force. Brinell Testing. Brinell testing normally is used for larger, heavy-walled pipe. Because the Brinell test is not a depth-measuring technique, it is more forgiving.

brinell hardness tester diagram

Brinell hardness test is most commonly used to test materials that have a structure that is too rough or too coarse to be tested using other test methods, e.g., castings and forgings. . The reading microscopic has a 25-fold magnification.The gap between successive graduations of the scale is 0.5mm and a micrometer is arranged sideways, the .The diameter of the indentation made on the material’s surface by a spherical indenter—typically a hardened steel ball—is used to calculate the Brinell hardness number (HB). Calculation of Brinell Hardness testing. Brinell hardness testing is used to measure the hardness of materials, particularly metals and alloys.

Rockwell hardness testing, Brinell hardness testing, and microhardness testing are all methods used to verify heat treatment results. Capabilities. Processes. Heat Treating. Annealing; . On the flip side, too-heavy loads could punch all the way through a case, ruining the chance of getting an accurate hardness reading. Precise specs that .

★the Hammer Hits the Brinell Hardness Tester with a Reading Microscope. ★ Small Size, Easy to Carry and Easy to Operate. ★ Accuracy Is in Accordance with Jjg 411, Iso9001:2000. . 2x Brinell Hardness Test Block: 2pc. 1x Box. What's in the box ; 1x Hardness Tester, 1x Reading Microscope (20x), 2x Brinell Hardness Test Block .indentation and impression reading using image analysis. Significant improvements over the past few years in hardware, image algorithms, electronics, and software capabilities have opened the door to . ASTM E110-14: Standard Test Method for Rockwell and Brinell Hardness of Metallic Materials by Portable Hardness Testers ASTM E18-16: .Brinell Hardness Testing Equation. Table A Brinell Hardness to Rockwell Hardness Conversion Table . Brinell Hardness: Rockwell Hardness: Tensile Strength (Approximate) Psi: Tungsten Carbide Ball 3000 KG: A Scale 60KG: B Scale 100KG: C Scale 150KG-85.6-68.0--85.3-67.5--85.0-67.0-767: 84.7-66.4-757: 84.4-65.9-745: 84.1-65.3-733: 83.8-64.7-722: 83 .

The Brinell hardness test (HBW) indentation leaves a relatively large impression, using a tungsten carbide ball. The size of the indent is read optically. . If the specimen is not properly cleaned after mechanical preparation and you perform an optical reading of the hardness test, an automatic reading might result in a misinterpretation of .The Brinell hardness test is an optical testing method for samples with coarse or inhomogeneous grain structure. This is the best test method for achieving the bulk or macro-hardness of a material, particularly those materials with heterogeneous structures. . 🕑 Reading time: 1 minute. The Brinell hardness test is an optical testing method .History Behind the Brinell Test. Let’s take a quick glance at the history behind the Brinell test. In 1900, Dr. J.A. Brinell invented this test. As an honor to him, the test named as a Brinell test. It is the oldest hardness test of all time. This test is used to .

Brinell hardness testing, widely used in industrial applications, determines metal hardness based on the size of indentions caused by specific indenters. Developed by Johan August Brinell in 1900, this method uses a tungsten carbide ball as an indenter. Brinell Hardness Number (BHN or HBW) is calculated by measuring the depth of the indentation . When choosing a microscope for reading your Brinell test indents, there are a few things to consider. Let King Tester help you improve your Brinell testing! . The result is then converted to HBW (Hardness Brinell), by looking up the measurement on the chart or table, to provide the hardness value (HBW).As shown in Fig. 3.12, the Vickers hardness curve remains practically straight at all hardness values, whereas at hardness above 300 kg/mm 2 the Brinell hardness curve starts bending to result in a lower value and it diverges remarkably causing an unacceptable hardness value above 600 Brinell, where the Vickers test is considered to be a . Hardness testing is a vital process in many industries. Our guide explains everything you need to know about this crucial technique. . Selection Table of Brinell Hardness Test P/D 2. Material type: Brinell hardness number/HB: . This method allows for direct reading of the hardness value and is highly efficient, making it suitable for batch .

Brinell Hardness Testing: Involves applying a known load to the surface of the test sample via a hardened steel or carbide ball; Vickers Hardness Testing: . Over-Relying on a Single Reading: One of the common mistakes is relying on a single reading. It's always better to take multiple readings in different areas and use the average value.

brinell hardness test theory

Hay Moisture Meter tv shopping

In the Rockwell hardness test, a differential-depth method, the residual depth of the indent made by the indenter, is measured.In contrast, the size of the indentation is measured in the Brinell, Vickers and Knoop optical test methods.. The deeper a defined indenter penetrates the surface of a specimen with a specified test load, the softer the material that is being tested.

The test provides numerical results to quantify the hardness of a material, which is expressed by the Brinell hardness number – HB. The Brinell hardness number is designated by the most commonly used test standards (ASTM E10-14[2] and ISO 6506–1:2005) as HBW (H from hardness, B from brinell and W from the material of the indenter, tungsten .Though loads of 500, 1000, 1500, 2000, 2500, and 3000 N are available in a typical Brinell hardness tester, a load of 500 N is used for testing relatively soft metals such as copper and aluminium alloys, while the 3000 N load is often used for testing harder materials such as steels and cast irons.However, the general rule is that the combination of test load and ball diameter .

Digital Waste Paper Moisturizer tv shopping

brinell hardness test pdf

web23 de ago. de 2021 · HOW TO USE RF CLICKER AUTO KILL AND AUTO LOOT - YouTube. 0:00 / 5:42. RF Clicker .

brinell hardness test reading|brinell hardness test pdf